| CONCEPT: |

|

Aerodynamics:

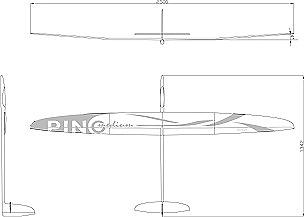

We

have developed a modern and fast airfoil for

Pino. The thickness is only between 6,16%

and 7,58%.

The aerodynamic design includes 5 different airfoils.

So there is the optimum airfoil for every spot on the wing.

The

creation of the airfoils was done with X-Foil, the wing aerodynamics

with XFLR5. Flaps

and the low weight provide good slow flight characteristics.

We

chose an all

moving tail for the

elevator for a quick and easy installation and

for performing abrupt aerobatic maneuvers.

In addition, Pino has extra strong airbrakes, which

are especially helpful on the slope.

A high degree of prefabrication ensures low building

effort and time.

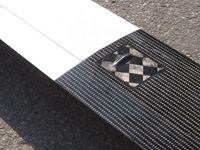

In

addition, it was important for us to use the most modern

materials and technologies, such as IMS Spread-Tow from

Russia, 39g biaxis non crimp carbon (Carboline), black-colored

glass, full core technology, spring-loaded contacts for electrical

connection and many more.

Pino

best described in a few keywords:

-

great dynamics thanks to modern aerodynamics

- very agile for optimum aerobatic fun

- easy to control in the border area therefore

- optimal thermalling characteristics and

- dead easy handling

- universal application

- due to the moderate size ideal for transport in your

car or backpack

|

| FUSELAGE: |

|

|

The

fuselage is a carbon construction using IMS-Spread-Tow

carbon. |

|

| The

fuselage cone is manufactured in black glass to ensure good

receipt of 2,4GHz. |

|

| The

servos for controlling the stabs are situated

in the fuselage. The servos are mounted in pre-cut

holes (KST X08-V3) inside

the fuselage cone. |

|

|

The

wing is placed on the fuselage from the top and fixed with

screws.

The electrical connection is made

with spring-loaded contacts, which also favor a damage-free

shearing off the wing.

|

|

| If

you use plastic screws, you can minimize the damage

in case of a crash. The wing will get off the fuselage

easily, as the screws act as predetermined breaking point. |

|

| The

model is also available as electric version. |

|

| WING: |

|

|

The

wing is produced in a special building method with a

stiff shell without sandwich. Multiple transport and

landings in rough terrain don't create permanent dents on

the wing as this is the case with sandwich-constructions.

All that remains are possibly some scratches.

Upper sides are painted, undersides left in visible

carbon.

|

|

| The

classic spar is replaced by 6 single carbon webs.

|

|

| Cutouts,

such as for installing the servos, are prefabricated. |

|

Precise

and simple mounting of the levers by prefabricated

recess: Just put in lever, superglue, done.

Gap

covers of the control surfaces on wing and tail are made

of a special masking tape as it is common with passenger-carrying

high performance gliders. The advantage: less disruption

of the flow and lower weight than the conventional

resin-based gap sealing lips.

|

|

| The

servo boxes were designed for all standard servos,

specifically: KST DS135MG |

|

|

Easy

system for ballast by varying the connectors

Enclosed in the kit:

1x carbon connector

1x steel connector short

additionally 2 short steel bars for both wing halves

Available

on demand:

1x

Steel connector long

additionally

2 long steel bars for both wing halves

|

|

| All

control surfaces are mounted with kevlar. |

|

| Carbon

covers for servos are enclosed in the kit. |

|

| STABILIZER: |

|

| The

rudder is built in full-core-construction with Rohacell

as core and 75g biaxis non crimp

carbon as outer skin. Linkage and levers for controlling

the elevator are already integrated inside the

rudder. |

|

| The

elevator is also made with a core of rohacell, but

coated with 75g biaxis non crimp

carbon. Upper side is painted, underside

left in visible carbon. |

|

| The

elevator can easily be removed. |

|

| ACCESSORIES: |

|

| Kitparts are enclosed in kit. |

|

| Protection

bags made

of

welded bubble wrap coated

with aluminium foil

(not included in kit) |

|

Protection

bags made

of stitched foam material coated with aluminium foil

with fabric edging and practical

velcro fasteners

(not included in kit) |

|

| Servos

are

available at extra cost. We recommend KST X08-V3 for

the stabs and KST DS135MG for aileron and flap. |

|

|

Matching servo frames for the wing servos are included,

if you order servos.

|

|